Recultivation principles of destructed silts

in oil pipeline construction

Исмаилов

Нариман Мамед оглы,

доктор биологических наук, профессор,

Сулейманов

Бахруз Аллахверди оглы,

кандидат физико-математических наук,

Панахова

Айтекин Акбер кызы,

аспирант.

Институт радиационных проблем

Национальной Академии Наук Азербайджана.

Ismailov

N. M.,

Suleymanov

B. A.,

Institute of Microbiology of Azerbaijan

National Academy of Sciences,

Panahova

A. A.,

Institute of Radiation Problems of

Azerbaijan National Academy of Sciences.

Introduction

Apparently,

the laying of the main pipeline of hundred kilometers in length is accompanied

by destruction of hundreds hectares of fertile soil. In case of pipelines lining

ground can and should be restored.

It

is important to restore silt at the main pipelines construction. While

developing rehabilitation projects there are defined the followings:

·

Borders of arable lands on a pipeline where

rehabilitation is necessary.

·

Thickness of a removed fertile layer on each part.

·

Width of a rehabilitation zone within the limits of a

strip of allotting.

·

Location dump for permanent storage of a removed

fertile layer.

·

Permissible destruction of the level fertile layer

above broken lands.

·

Removal, transportation and laying ways of a fertile

layer.

·

Scopes and methods of loading and export of a

superfluous mineral silt, and its unloading in specified places for the purpose

as well.

·

Methods of packing of the loosened mineral ground and

a fertile layer of ground after covering of the

pipeline.

Rational

rehabilitation of the lands during the construction of the main pipelines

allows the reducing scope of excavations, the saving biologically active silt layer

pollution and considerable reducing of soil and environment.

Basic

approaches used in remediation

According

to market testing remediation technology is developed on directions focused on purification

ground and reservoirs from the most various pollutants. In this connection

there are developed and used more than 27 types of technologies of environment purification

of a technical, physics- chemical and biotechnological orientation [1, 2, 3, 4].

Physical

and chemical methods differ from biotechnological ones with high standardization

result application technology, efficiency and predictability, but lose at the

expense of rigidity of influence on ground and the raised cost on 10-40 %.

Correspond

to the chemical methods of ground rehabilitation constitutes ground processing with

highly active adsorbents, such as lime treatment,

sulfate of sodium, ferric oxide, gypsing with

washing, adding organic and mineral fertilizers.

One

of the methods providing dispersion of oil pollution and improving contact with

microorganisms is surfactants adding. Washing substances wash mineral oil away from

silts together with water. The application combination of surfactants with

mineral fertilizers accelerates biodestruction.

Remediation or

bioremediation

Effectively

joint utilize of physic-chemical and biological methods are economical favour

at high levels pollution as well. Among physic- chemical methods from the ecology

point of view purification methods oil polluted ground in hydro cyclones is

most comprehensible at biologically decomposed surface-active substances

utilities. While effective solvents utilities oil of various mechanical structures

is wished away from ground the technology which provides safety of functional

activity of soil microbiotas and processing biodegradation of residual oil is

carried out. [3,11].

Addition

of oil decomposing microbial preparations, oil microflora (biota) directed activation

and long-term herbages seeding phytomelioration correspond to biological

methods as well.

Main principles of

bioremediation technologies.

Biotechnological methods supply microorganisms; application capable to

utilize various pollutants. The meaning of the term bioremediation: a

bio-life (Greek), remedio - to treat.

The

leading factor of self purification of oil polluted silts under natural conditions

is the biological factor. It’s based on the ability of microorganisms to

decompose a wide spectrum of organic compounds contained in polluted silts.

However under natural conditions self-purification process of silts from oil

hydrocarbons processes slowly and depends on aeration degree, oxygen availability,

nitrogen sources, phosphorus, etc.

Nowadays aerobic bacteria are mainly

utilized at the biopurification process. Researches showed their ability in

active hydrocarbons decomposition, demands according to existent as the most

effective for the growth were determined. Their metabolism has been

investigated in detail and it showed that products processed by microorganisms

of mineral oil products are not dangerous for a man and environment. The most utilized

biological preparations on the development of hydrocarbon oxidizing

microorganisms bacteria corresponding to Pseudomonas, Rhodococcus, Bacillus,

Arthrobacter, Acinetobacter, Azotobacter, Alkaligenes, Mycobacterium genera are

concerned; yeast Candida genus; threadlike actinomycetes of Streptomyces; the

fungus corresponding Aspergillus’s and Penicillium genera and other micromycetes.

Biostimulation in situ. This approach is based on stimulation of

natural (indigenous) growth of microorganisms contained in polluted soil and

potentially capable to utilize the pollutant, activity of which is suppressed because

of absence or lack of number of biogenic substrates - nitrogen, phosphorus,

potassium, etc. In this case by laboratory researches it is possible to determine

the following with the use of polluted soil samples; biogenic elements and

their quantity necessary for adding to the polluted soil to stimulate the growth

of the microorganisms, capable to decompose a pollutant. Many firms have been

patented bioadditives which have stimulating effect on a wide spectrum of the

microorganisms capable to utilities plenty of the pollutants [6, 8, 10].

Biostimulation in vitro differs for its sample biostimulation of

natural micro biota of polluted silt or water which is conducted at the start under

laboratory or industrial conditions (in bioreactors or in fermenter). Thus the

bioreactor primarily supplies selective growth of these microorganisms which

are most capable for effective pollutant utilization. Thus stimulated microorganisms

with necessary biogenic compounds increasing efficiency pollutant utilities are

added simultaneously as well [11].

Bioaugmentation («bioimprovement»). In this

case enriched with a plenty of the specialized microorganisms added to the

polluted soil selected beforehand from various polluted sources were

genetically modified. In the process of bioaugmentation alien microorganisms are

often added to the soil alien for it. After utilization of the pollutant the

quantity of viable alien microorganisms added to the soil from the outer mass

should be sharply decreased [7].

Below on the circuit there are shown the basic

stages of microorganisms’ selection - destructors from the polluted objects.

Microbial

screening and the analysis

Soil samples

|

↓

Definition of the number of oil oxidizing microorganisms

|

↓

Screening on various hydrocarbons

|

↓

Selection

|

↓

Identification

|

↓

Creation of microorganisms’ collection

|

↓

|

Creation of biological preparations

|

At

a method bioremediation choice - biostimulation in situ or in vitro one of the essential

parameters are those parameters of microbial system status of object. Such

parameters are number and biomass of microorganisms, correlations of

saprophytes and oil oxidizing microorganisms and direct correlation is detected

out among the number of populations of microorganisms and intensity of pollution,

otherwise it is absent.

Scales

can be used for a level rating of soil enrichment by microorganisms (tab. 1).

Tab. 1.

Scales for biostimulation methods of planning utilization depending on

enrichment an level of soil by microorganisms.

|

soil enrichment level |

Total number of

bacteria |

Dry bio-mass of bacteria |

Length of fungi |

Dry bio-mass of

fun-gi |

Number of bacteria

on Meat medium agar |

Number of bacteria

on Еshbi, Chapеcs and SAA (starch ammonium agar) |

Possible methods

of biostimulation ( in situ, in

vitro) |

||||

|

Mlyd/q |

Mlyd/ sm2 |

kq/ ha |

mq |

m/ sm2 |

kq/ ha |

mln/q |

mln/ sm2 |

mln/q |

mln/ sm2 |

||

|

Very pure |

1 |

50 |

42 |

30 |

750 |

120 |

1 |

25 |

1-2 |

50 |

in vitro |

|

pure |

1-2 |

50-100 |

42-85 |

30-100 |

750-2500 |

120-400 |

1-2 |

25-50 |

2-4 |

50-100 |

in vitro |

|

average |

2-5 |

100-200 |

85-170 |

100-300 |

2500-7500 |

400-1200 |

2-5 |

50-125 |

4-10 |

100-250 |

in situ |

|

Rich |

5-10 |

200-400 |

170-340 |

300-1000 |

7500-25000 |

1200-4000 |

5-10 |

125-250 |

10-20 |

250-500 |

in situ |

|

Very rich |

>10 |

>400 |

>340 |

>1000 |

>25000 |

>4000 |

>10 |

>250 |

>20 |

>500 |

in situ |

Cost of bioremediation

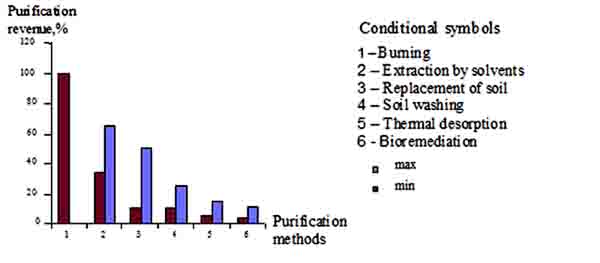

Nowadays

bioremediation methods are the most comprehensible from ecological and economic

points of view [5] (pic.1). Methods are used for purification of ground surface

on depth up to

Picture 1. Economic

purification profit oil polluted silts by different methods.

To

intensify process of decomposition of oil hydrocarbons (five and more times) is

possible by artificial adding to the soil the pure or mixed cultures of hydrocarbon

oxidizing microorganisms as biological products. Biological preparates made by

business concerns, represent a biomass of viable hydrocarbon cells oxidizing microorganisms

and differ in their reception application with especial physiology-biochemical properties,

Nowadays the market offers a big variety of biological preparation: Uni-Rem,

Petro, Petro trite, Avalon, Roder, Ekoil,

Fechel-bio, Devoroil, Econadin, etc.

The

utilization of genetically modified microorganisms for bioremediation can be

expedient when their biochemical characteristics providing bioremediation are

improved, and the spectrum decomposed pollutants is distributed, genetic

updating provides (or increases) the stability of microorganisms for the environmental

factors (stability on heavy metals, high concentration of salts, etc.), allows

to operate the vital functions of a microorganism and by that to supervise

their growth and activity.

References

1.

Velkov V.V. (1995). Bioremediation: principles,

problems, approaches. /Biotechnology, №3-4, p.20-27. (In Russian).

2.

3.

5.

Sinkova E.A. (2006). Rational ways to sanities of centers

pollution technogenic by hydrocarbon connections. // Sank-Petersburg, 25p, (In

Russian).

6.

Bayrai R.K., Zappi M.E., Gunnison D. (1994). // Annals

of the New York Academy of Sciences, v.721, p.450-465, (In

English).

7.

Bewley R.J.F. Release of Genetically Modified

Microorganisms –REGEM 2/Eds. D.E.S.Stewart Tull, M.Sussman.-N.Y and

8.

Bragg J.R., Pribce R.C., Harner E.J. ET all. (1994). //Nature,v.368,

N.6470, p.413-418, (In English).

9.

Funk S.B., Roberts D.J. and Crawford D.L. ET all.

(1993). // App. and Environmental Microbiology, v.59, №7, P.2171-2177, (In English).

10.

Mills S.A.,

Frankenberger W.T. (1994). //Bull. Of Environmental Contamination. And Toxicology,

v.53, N2, P.280-284, (In English).

11.

Shouche M.S.,

Petersen J.N., Skeen R.S. at all. (1994). //App. Biochemist and Biotechnology, v.45,

N6, p.775-785, (In English).

Поступила в редакцию

15.10.2009 г.