Консистенция сгущенного вареного молока с глюкозно-фруктозными

cиропами

Гуць Виктор Степанович,

професор, доктор технических наук, кафедра безопасности жизнедеятельности,

Шпачук Людмила Владимировна,

ассистент кафедры экспертизы пищевых продуктов.

Национальный университет пищевых технологий, г. Киев.

Eeffect of glucose-fructose syrup the consistency of condensed milk

V. S. Guts,

Dr. Sc., Professor.,

L. V. Shpachuk,

Assistant.

National University of Food Technologies, Kiev.

The article describes the current state of the use of natural artificial sweeteners, especially glucose-fructose syrup (GFS) in the food industry.

Theoretically proved and experimentally demonstrated the possibility of using glucose-fructose syrup in the technology of concentrated caramelized milk. The research of quality characteristics was done and defined consistency of concentrated caramelized milk by using glucose-fructose syrup.

The present methods of determination of the consistency of experimental samples by the method of gravitational penetration is describe . The data of experimental research of change of penetration index of the prepared product during storage are given .

On basis of the carried out studies is founded that the introduction of glucose-fructose syrup promotes the formation of soft consistency concentrated caramelized milk. The relation between the assessment of consistency of concentrated caramelized milk and the indicator of penetration is displayed.

Developed recipe of concentrated caramelized milk with glucose-fructose syrup can be recommended for the production on the enterprises of canned milk sector.

Keywords: condensed milk, glucose-fructose syrup, consistency, gravitational penetration.

All food products are very difficult after chemical composition, have definite characteristic that in general characterize production quality. Basic determination of estimation of products quality is organoleptic estimation, to that belong external appearance, taste, smell, colour and consistency. However this method of determination of consistency is subjective and doesn’t give a complete idea about consistency of food products. Therefore in the process of determination of product quality, with organoleptic method of estimation consistency is necessary to apply the instrumental methods of control that are based on determination of one or a few objective of structurally-mechanical description of products.

Consistency is a part of structurally-mechanical properties (SMB) and characterize the aggregation state of products and it is external expression of internal structure of dispersed system and the type of cooperation of structural elements in a product. Structurally-mechanical properties show up during operating of mechanical energy (force) on a product and characterize his resistance to the added forces. The group of physical properties describes the full idea about some aspects of production quality.

Most food products are the difficult heterogeneous systems. Their structurally-mechanical properties are individual and depend on many factors: temperature, humidity, mass part of fat, concentration of dry substances.

The caramelized condensed milk is characterized with high maintenance of sugar that gives specific taste and provides the preserve effect of the prepared product. It is known that the unnormalized use of products with high maintenance of carbohydrates results in the row of dangerous diseases. Therefore, a tendency was lately formed to the production of food products with application of sugar substitute or products with law content of sugar [1; 5].

Analytical researches witnessed that among plenty of sugar substitute that is used in food industry abroad, glucose-fructose syrups appeared one of most perspective for a mass consumption. They on taste properties compete with a beet and sugarcane and more safe food product after the composition.

Glucose-fructose syrups after the composition are differ from sugar syrup, that is why researches of their influence on structurally-mechanical properties of the caramelized condensed milk are actual, so as consistency of the condensed milk influences on efficiency of technological processes and quality of product.

The aim of work consists in research of consistency of the caramelized condensed milk.

The article of research is the caramelized condensed milk with natural sugar substitute - by glucose-fructose syrup.

Research methods. Consistency of experience tests of the condensed milk determined by means of method of gravitational penetration.

Exposition of basic material of research. For determination of influence (GFS) on consistency of the caramelized condensed milk four standards of products were investigated: the first standard - the caramelized condensed milk with sugar syrup (control); the second - the caramelized condensed milk with glucose-fructose syrup and sugar syrup in correlation 50: 50 accordingly (GFS – 10); the third - the caramelized condensed milk with glucose-fructose syrup (GFS – 30); the fourth - the caramelized condensed milk with glucose-fructose syrup (GFS – 42).

Composition of the boiled condensed milk is presented in table 1.

Table 1

Quality descriptions of the сaramelized condensed milk(% in 100 gs of product)

|

Components |

Condensed milk is treats thermally, made from |

|||

|

Standard 1 (with sugar (control)) |

Standard 2 (GFS-10) |

Standard 3 (GFS-30) |

Standard 4 (GFS-42) |

|

|

Mass part, % |

|

|

|

|

|

Carbohydrates, %, including: - lactose - saccharose - glucose - fructose - maltose - higher sugars |

12 43,5 - - - - |

12 21,5 8,3 3,7 6,1 3,4 |

12 16,6 17,3 8,1 1,1 |

12 - 20,8 21,1 1,2 0,4 |

|

Fat, % |

8,5 |

8,5 |

8,5 |

8,5 |

|

Protein, % |

6,29 |

6,16 |

6,24 |

6,53 |

In the process of stowage of compounding was determined, that the caramelized condensed milk is not expedient to prepare with the use of only one syrup, as this syrup does not provide the product of the proper sweetness, what peculiar to the traditional product. Therefore an optimal decision is the use of syrup only for partial replacement of sugar. Syrups GFS – 30 and GFS -42 give an opportunity of complete replacement of sugar in a product. Such products contain on 4-7% carbohydrates less than in comparing to traditional that in turn reduce calorie content of the condensed milk.

For determination the consistency of product is used penetrometer, viscometer, consistometer, adhesiometer and others. On the modern stage of development authenticity of results of experimental researches is arrived at due to the use of modern measuring devices, mathematical models and computer techniques. Therefore it was selected a new simple and simultaneously scientifically reasonable method of needle-shaped penetration.

This method envisages immersion of needle-shaped indenter mass of m (g); diameter d (mm) in a product.

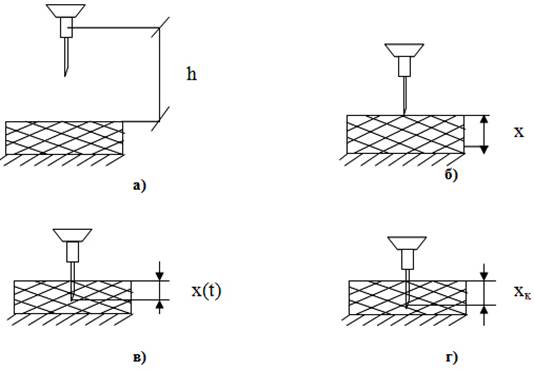

On picture1. the sequence of immersion of needle-shaped indenter is shown in a product:

Picture 1. A sequence of immersion of indenter is in a product.

Researches conducted in a next sequence. An indenter was fastened on

height of h from the centre of his gravity to the standard ( picture1a). He was

released and under the action of attractive power an indenter fell on a

standard. At a contact with the surface of standard his speed will equal V0=![]() (where, g=9,8 –

acceleration of the free falling, м/с2). Farther

an indenter began to dip in the layer of standard. Next forces will operate at

this time: gravitation Рт =

mg; penetration Рпр=φ(Коп) that is the function of structurally-mechanical properties of

product and characterizes his consistency; the force of inertia of Newton: Pn =m

(where, g=9,8 –

acceleration of the free falling, м/с2). Farther

an indenter began to dip in the layer of standard. Next forces will operate at

this time: gravitation Рт =

mg; penetration Рпр=φ(Коп) that is the function of structurally-mechanical properties of

product and characterizes his consistency; the force of inertia of Newton: Pn =m![]() ; what is description of motion of

the system.

; what is description of motion of

the system.

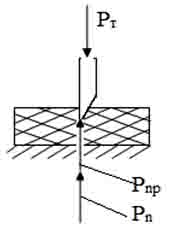

On picture 2. is schematically shown the action of forces at immersion of needle-shaped indenter in the layer of product.

Picture 2. Forces that operate on a needle-shaped indenter.

Will write down differential equalization of motion of indenter, taking into account the higher described forces:

m ![]() (1)

(1)

A decision of equalization(1) is at the initial

conditions of t 0= x(0) = 0 ![]() =V0:

=V0:

x(t) = ![]() (2)

(2)

Coming from the terms of realization of experimental researches, an analysis of the conducted mathematical model can be different. Modern experimental options allow simultaneously fix the depth of immersion of indenter and duration of process. Putting their value in equalization (2) we find an effort Рпр .

It was offer considerably more simple method of determination of force of penetration Рпр. The sequence of realization of research is the following. First weigh an indenter and fix his mass, whereupon fasten an indenter on a stand and measure off distance h from the centre of gravity of indenter to the standard. Farther release an indenter and fix the depth of his immersion хк. To search out the duration t of immersion of indenter executes differentiation of equalization:

![]() +V0 (3)

+V0 (3)

Penetration will be complete, when the rate of movement of indenter

will be zero that is ![]()

![]() + V0

+ V0

Taking into account it find t:

t = ![]() (4)

(4)

Put t in equalization (2) :

xк = ![]()

![]() (5)

(5)

From equalization (5) find Рnp:

![]() (6)

(6)

Use equalization (6) to find out the force of Рпр of penetration

At determination of character of influence on consistency of product factors of technological character, for example, of temperature, duration of treatment, mechanical influence, concentration of substance and many other. Expedient is determination of change of consistency-index of penetration.

In this case expect the relation:

φ

=![]() ; (7)

; (7)

where, хк.опт - immersion of penetrometer in a product with optimal consistency, certain an organoleptic method. The comparative analysis of data of experimental researches on gravitational penetrometer and by means of organoleptic researches is driven to table 2.

Table 2

Estimation of consistency of the caramelized condensed milk

|

Consistency of product (organoleptic determined) |

Index of penetration Φ |

|

Very soft consistency, fluid, Soft but not fluid Optimal consistency Satisfies the necessities of high quality Fairly hard consistency Hard consistency |

≤0,5 0,5÷0,8 0,8÷1,1

1,1÷1,5 ≥1,5 |

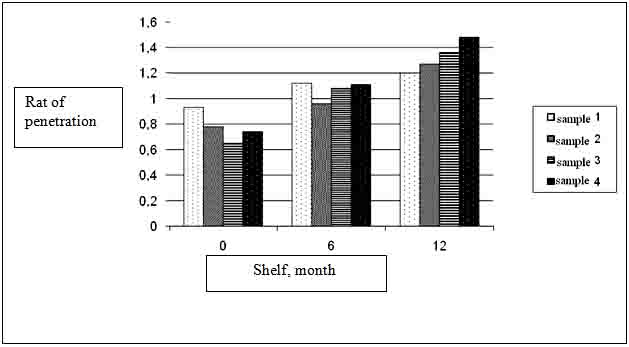

The results of researches around the penetration of consistency of the caramelized condensed milk with different carbohydrate composition are described on picture 3.

Picture 3. A change of index of penetration of the caramelized condensed milk is at storage.

The results of researches evidently that the caramelized condensed milk with glucose-fructose syrups in freshly prepared standards has more soft consistency in comparing to the control standard. However already in 6 months of storage consistency of standards of the condensed milk with glucose-fructose syrups got around control. Index of penetration of the caramelized condensed milk from GFS - 30 and GFS - 42 during 6 months of storage increased on 16,6 and 15% accordingly, while the caramelized condensed milk with sugar - 10,2%. In 12 months the coefficient of penetration of the boiled condensed milk rose: control - on 12,9%; from GFS 10 - on 16,3%; from GFS 30 - on 20,9%; from GFS 42 - on 20%. In freshly prepared standards of the condensed milk from GFS consistency a little bit softly as compared to control, but with the increase of data expiration of penetration coefficient increases, that testifies to formation of more hard by organoleptic estimation consistency.

Conclusion

On the basis of experimental researches the index of penetration of the condensed milk is set with glucose-fructose syrups by means of method of gravitational penetration. This method gives an opportunity objectively define the consistency of the prepared product made with substituting of sugar by glucose-fructose syrups and to set character of her change depending on duration of keeping.

The list of literature

1. Горбатова А.В.Структурно-механические характеристики пищевых продуктов. М. - Легкая и Пищевая промышленность, 1982-237с

2. Перебейнос А.В. Технологии производства функциональной продукции из продовольственного сырья. М. - Легкая и Пищевая промышленность, 2002-230с

3. Рогов И.В. Физические методы обработки пищевых продуктов. М. -Пищевая промышленность 2004-584с

4. Федоров Н.Е., Измерение ротационным вискозиметром. М. - Легкая и Пищевая промышленность, 2000-104с

5. Шалыгина А.М. Структурно-механические характеристики пищевых продуктов. М. - Колос, 2002-201с

6. Зобкова З. С., Фурсова Т. П. О консистенции молочних продуктов // Молочная промышленность – 2002. - №10. – с. 23-24.

7. Косой В. Д., Меркулов М. Ю., Юдина С. Б. контроль качества молочних продуктов методами фізико-химической механіки. – СПб.: ГИОРД, 2005. – 208 с.

8. Матц С. А. Структура и консистенція пищевых продуктов. – М.: Пищевая промышленность, 1972. – 238 с.

9. Скорченко Т. А.Сучасні тенденції виробництва молочних консервів // Молочное Дело. 2006. - №4. – с. 23 -24

10. Чекулаева Л. В., Чекулаев Н. М. Сгущенные молочные консервы. – М.: Легкая и пищевая промышленность, 1982. – 264 с.

Поступила в редакцию 11.03.2013 г.